CHAIN LINK FENCING:

As per IS 2721:2003 Rev.2

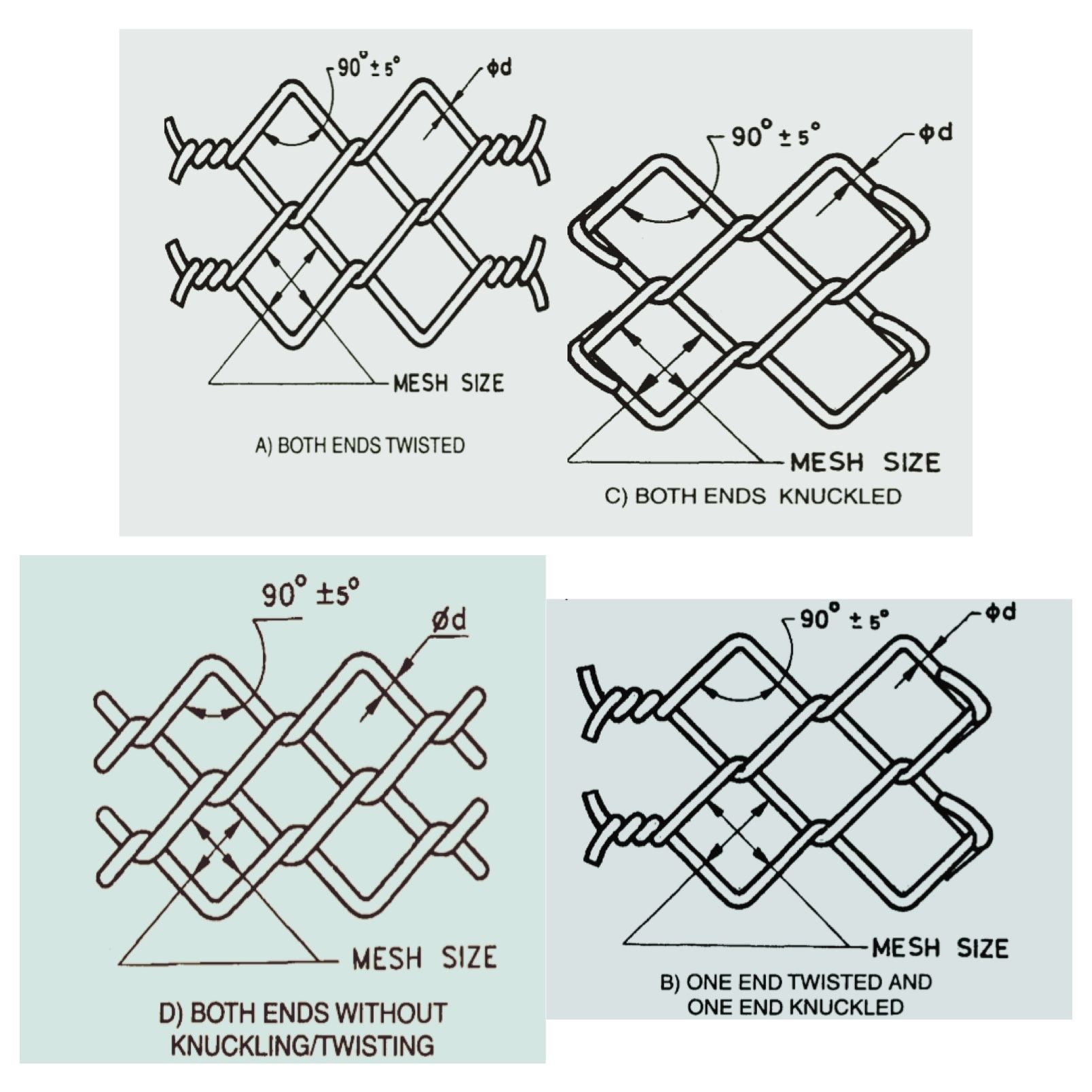

Fencing material made from steel wire from Mild steel wire with or without hot dipped Zinc coating helical wound and interwoven in such a manner as to provide a continuous mesh without knots or ties except in the form of knuckling or twisting the ends of the wires to form the selvage Knuckled or twisted as per requirement.

Length

The fabric shall be supplied in rolls of 5.0 m, 10.0 m,

15.0 m, 20.0 m, and 25.0 m, or as per the requirement

of the purchaser. The supplied length shall not be less than the above values when measured in fully stretched condition.

Tolerance on Wire Diameter

Tolerances permitted on the diameter of mesh and line wire shall be as given in IS 280.

Each roll shall be warranted to contain no weld joint or splice whatsoever. The wire shall be circular and shall be free from scales, irregularities, imperfections, flaws, sand splits, and other defects. The zinc coating shall be smooth, even, and bright.

The rust formation on the cut ends of the wire at the fabric selvages are an inherent characteristic of this material and does not warrant rejection of the fabric.

GALVANIZING

The chain link fence fabric shall have zinc coating of type ‘heavy’ as given in IS 4826 or in IS 12753. –The fabric shall be provided with heavily coated galvanized line wires, as given in Table to act as additional selvage to strengthen the fabric when used for fencing purposes or as per the requirement of the purchaser. The line wire may be supplied separately in coils/bundles/cut lengths to be used for fencingpurposes. The line wires are required to be inserted after erecting the fabric with straining posts. Two number of line wires for the fabric of height up to 2 m are to be provided one each at the top and bottom of the fabric.

Three numbers of line wire for the fabric of height 2.50 m and more are to be provided one each on the top, middle, andbottom of the fabric.